SFF Forum member K888D is aiming for the smallest, quietest SFF PC possible to fit a gaming system, at a budget that’s (hopefully!) under 100 quid (UK Pounds), in no small part due to the lack of risers or custom cabling.

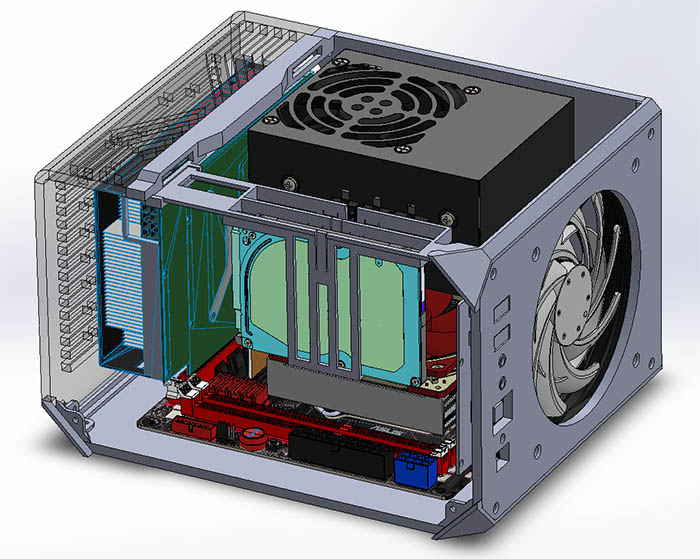

To meet that goal, they’ve designed the LZ7: a quiet gaming cube with an internal SFX PSU, and an overall volume that will be at or around just 6.9L.

[mks_separator style=”blank” height=”2″]

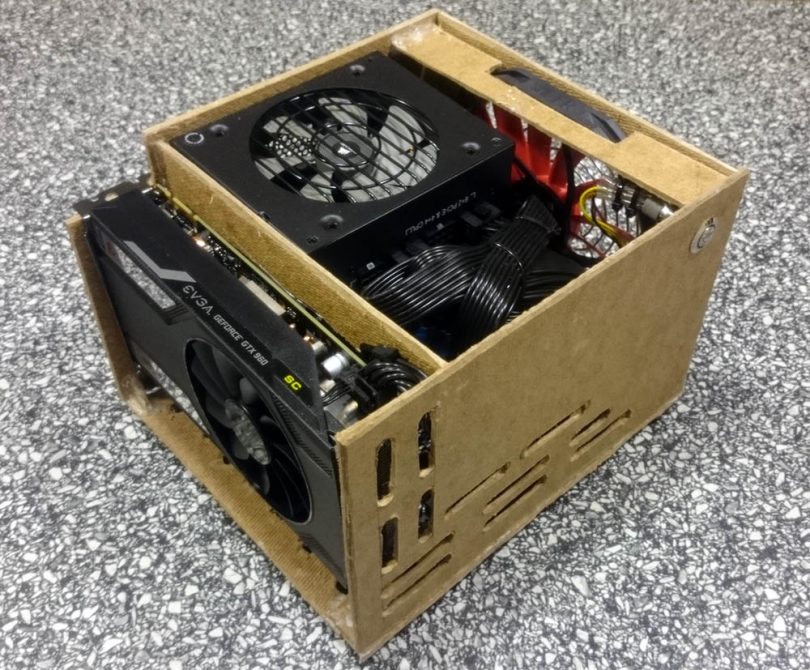

Initially, cardboard prototyping was used to get the basic shape and layout down – always a good idea, in our book. A few of our staff have experience designing and mocking up enclosures, and we know from experience that there’s just something that a physical prototype provides in the design process that 3D modelling/CAD alone just can’t achieve.

In any case, K888D made the decision early on to use 5mm acrylic as the case material, as well as to support a M-ITX motherboard, SFX power supply, and a full-height dual-slot ITX-style GPU.

[mks_separator style=”blank” height=”2″]

With a firmer sense of the final layout, a second plywood model was mocked up as a sturdier alternative to cardboard, which secondarily allowed K888D to test the use of a slim intake fan. From the cardboard model to this, a significant decrease in sound output was observed, as the CPU, GPU and PSU all had cooler air available to them.

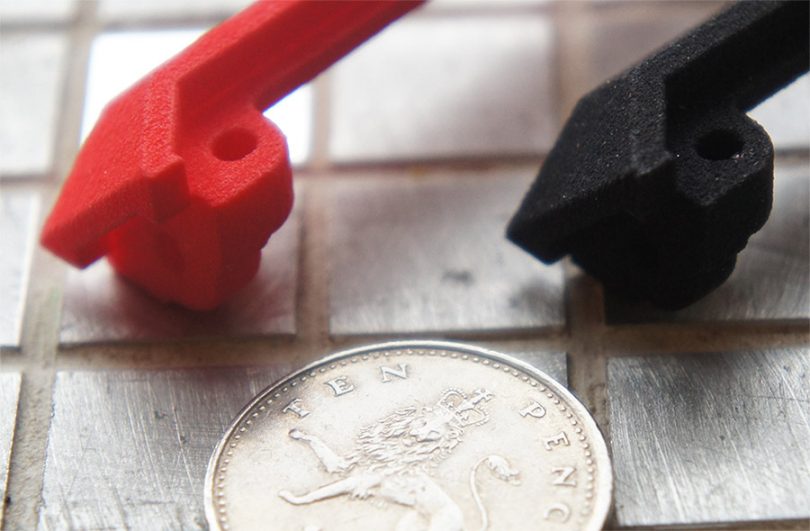

Next, after considering the use of T-Bolt type fasteners, K888D made the decision to go with custom, 3D printed corner pieces for usability and aesthetic reasons.

[mks_separator style=”blank” height=”2″]

Of course, with the aforementioned budget in mind, cost tracking was a necessary element of the design process, and it was at this point that the calculator was pulled out to check the math on materials. K888D calculated that the Acrylic panels were estimated to cost in the region of £25 – £30 for the complete set, and that the 3D printed parts were estimated to cost around £4 – £5 for each corner set. Not bad! As for brackets, K888D plans on designing a 3D printed HDD cage, which can fit up to 3x 2.5” HDD’s, and this will also be 3D printed.

[mks_separator style=”blank” height=”2″]

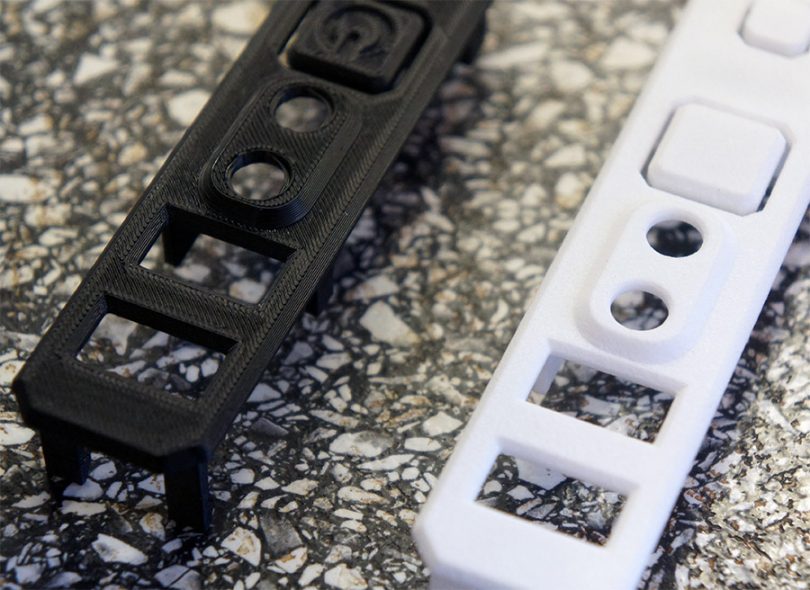

For the exterior ports, K888D was able to find a Corsair-sourced front I/O PCB for the build, around which K888D would design another 3D printed component, a custom front I/O shield.

[mks_separator style=”blank” height=”2″]

Further design iterations were forthcoming, including various vent designs:

[mks_separator style=”blank” height=”2″]

The front panel I/O shield was designed in CAD to work with the Corsair PCB:

[mks_separator style=”blank” height=”2″]

And here it is, 3D printed.

[mks_separator style=”blank” height=”2″]

Meanwhile, more design tweaks were made, adding a splash of color to the exterior!..

[mks_separator style=”blank” height=”2″]

…As well as more vent designs.

[mks_separator style=”blank” height=”2″]

Just recently, K888D received updated and better quality 3D printed parts:

[mks_separator style=”blank” height=”2″]

[mks_separator style=”blank” height=”2″]

And finally, the first corner pieces also arrived for testing!

[mks_separator style=”blank” height=”2″][mks_separator style=”blank” height=”2″]

This is but a brief summary of what K888D has done so far, towards the goal of a 6.9L Quiet Cube case, but color us impressed. K888D has since received parts and assembled them – but if you’d like to see the latest progress, and follow updates on the project, you should check out the original discussion right here!