When it comes to chip fabrication and emergent process nodes for silicon, Intel is almost always the company on the forefront of people’s minds: as the largest player in the semiconductor space, their tick-tock microarchitectural change model has set the pace in which ever-smaller transistor sizes are adopted by industry.

It came as a bit of a surprise, then, when IBM (of all companies) announced today that they’ve just leapfrogged Intel, by developing a lab-tested process that can yield 7nm chips. In fact, through a partnership with GlobalFoundries and Samsung, IBM has actually managed to claim a lot of important ‘firsts’ with their announcement, from the first commercially viable chip that’s sub-10nm, to the first chip design that relies on the nascent “extreme ultraviolet” lithography (EUV) process to etch transistors.

(To give a sense of just how small 7nm is, it’s worth nothing that the the thickness of a strand of DNA is pegged at around 2.5nm. Needless to say, we’re talking about some mind-bogglingly tiny circuitry!)

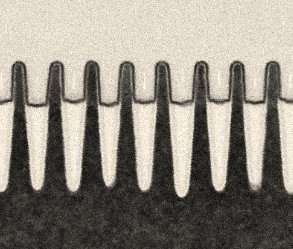

Getting to 7nm, then, certainly wasn’t easy, and IBM spent considerable time explaining many of the challenges they faced in making viable chips at that size. To start, they had to abandon pure silicon, and move to wafers composed of a silicon-germanium alloy, in order to keep the tiny transistors functional. IBM also had to abandon traditional lithography processes (which etch, or ‘draw’, transistors on a wafer) in favor of the aforementioned EUV process, which has enough resolution to scale down in size, but remain viable for use. And, of course, IBM’s consortium still has plenty of work to do with respect to scaling up their production methods: even with viable chips already made at the 7nm process node, much will need to be done in order to make that tech commercially workable as well.

Still, with 14nm chips from Intel already on the market, it can be quick for some to dismiss these achievements as minor in scope, so it’s important to emphasize the magnitude of the improvement that this smaller node can provide. As much as it might seem otherwise, the jump from 14nm to 7nm is simply immense, and that small numerical difference has a profound impact on relative performance: IBM itself projects that the transition from future 10nm chips to 7nm ones will yield power and performance improvements of over fifty percent. Further, the cumulative improvements coming from 14nm could be on the order of 2-4x performance-wise, spread across a span of three to four years.

For those who like to dive into the nitty-gritty of semiconductor development, IBM’s own press release goes into fairly granular detail with respect to the technology they’ve been developing up to today’s announcement – but if you want something more approachable, Ars Technica’s Sebastian Anthony has a fantastic (and somewhat more accessible) article covering the basics of IBM’s R&D work.

[mks_separator style=”blank” height=”2″]

Thoughts? Discuss them here.