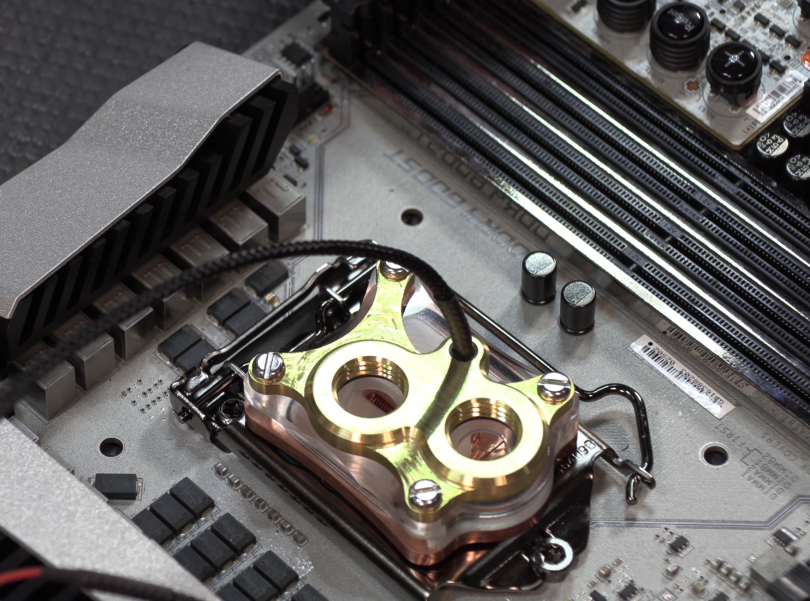

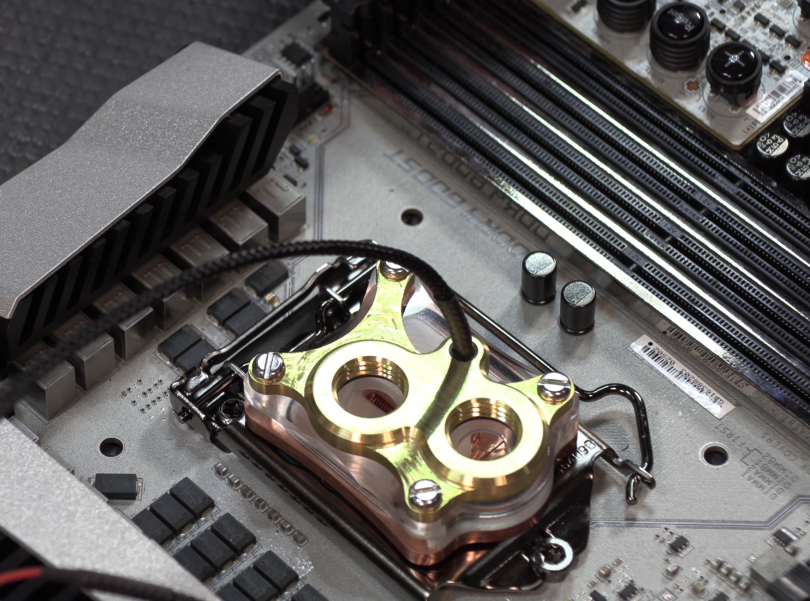

Over on HardOCP, Kyle Bennett has gotten his hands on a prototype waterblock from NUDEcnc, run by Arek Tobiszewski.

Unlike most waterblocks this tiny block mounts only on delidded Intel socket 115x boards by basically replacing the heatspreader as a part of the design. This allows the waterblock to make a direct contact with the CPU die meaning a much more efficient cooling.

It will be available for crowd funding on Kickstarter on April 1st.

Read more here (hardocp.com)

Unlike most waterblocks this tiny block mounts only on delidded Intel socket 115x boards by basically replacing the heatspreader as a part of the design. This allows the waterblock to make a direct contact with the CPU die meaning a much more efficient cooling.

It will be available for crowd funding on Kickstarter on April 1st.

Read more here (hardocp.com)