Sometimes the most appropriate cooler solution for a SFF rig is in fact the stock cooler. With this in mind, we set out to see which stock cooler for Intel’s socket 1155 was the better option, and by how much.

Specifically designed by the CPU manufacturer for your CPU, the stock coolers are commonly derived for their poor performance and awful noise output. In some situations, such as HTPC and home servers, the CPU load is usually low enough to enable any cooler to run at low speed. Other situations, like my LAN rig, flakb0x, involve a low wattage (< 65w) processor, and once again, the cooler can run slower.

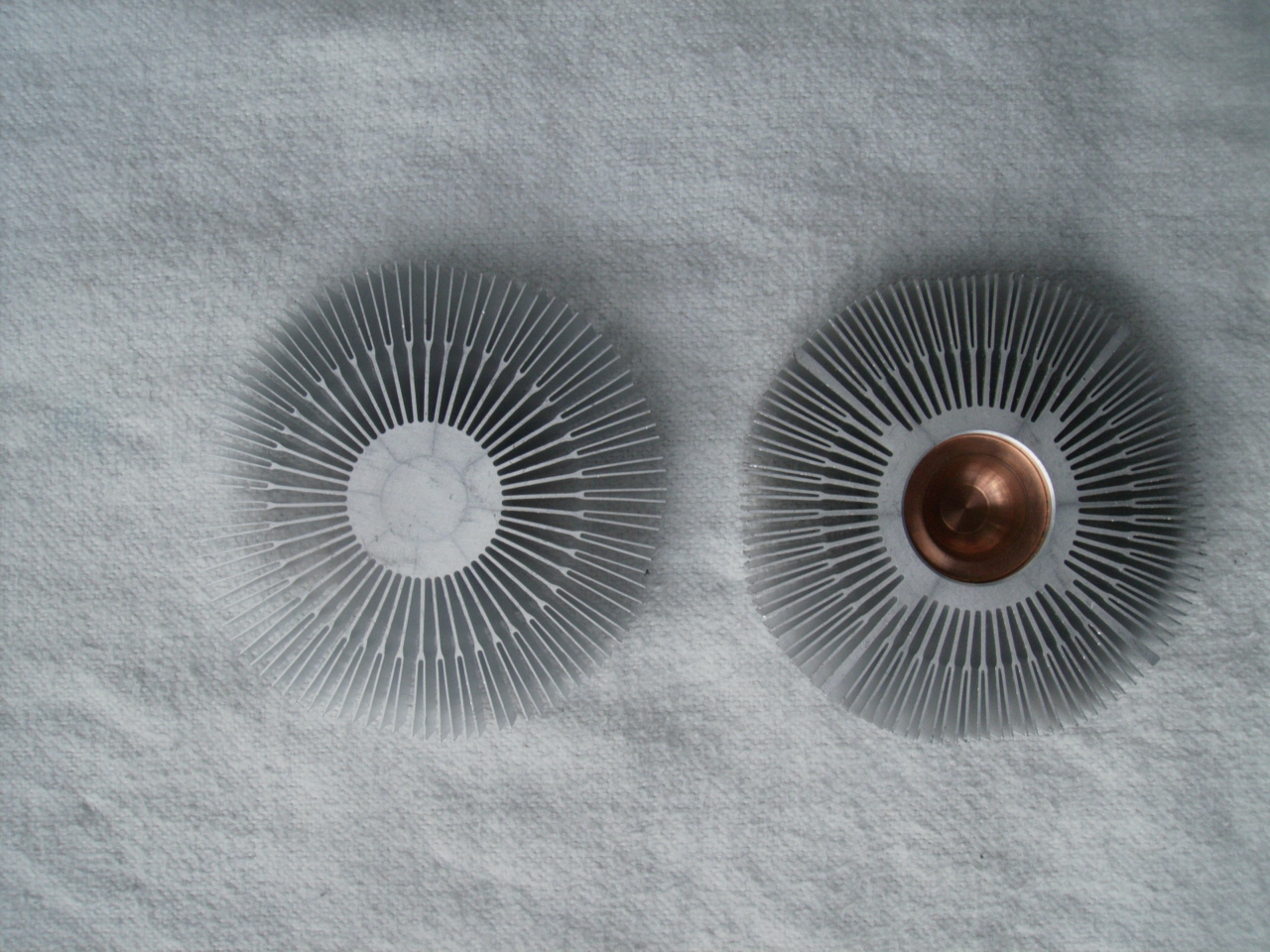

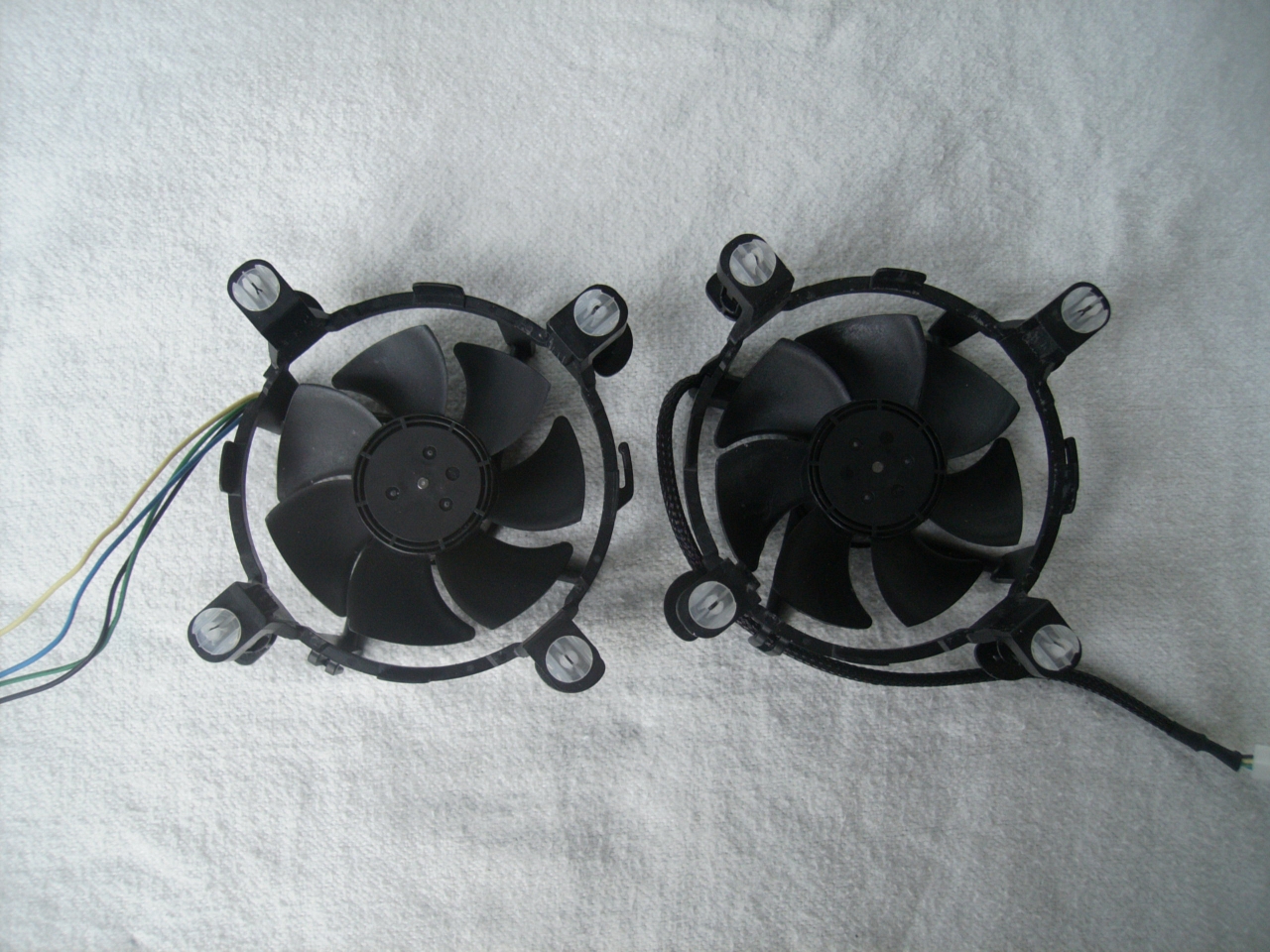

Today we are looking at two of the stock coolers that come with Intel’s socket 1155 processors. While similar in appearance, the looks can be deceiving. Both include aluminium as the main heatsink material, and have black, open frame fans. They have identical dimensions, but not ratings. The heatsinks are 45mm from CPU heatspreader to the top of the fan. They both have 90 mm fans, with an impeller width of 75mm.

Testing Methodology

We used the following system to test the coolers:

- Intel Pentium G620 (65w, Dual core)

- ASRock H61M-ITX

- 2x 2GB Corsair Value 1333MHz

- Western Digital Blue 3.5″ 500gb Hard Disk

- Sapphire HD5670 1GB

- Cooler Master 420W PSU

Firstly, we performed the idle test. This involved booting Windows, and letting the system sit idle on desktop for 10 minutes. The temperature is taken at 10 minutes.

The load test is performed with Prime95, LargeFFT. We let this run for 30 minutes, ample time for temperature to stabilise, and then recorded the temperature.

The load test is repeated with fan at 12 volts.

At all three temperature recording points, fan RPM is taken as well. We used SpeedFan to take temperature and fan speed measurements. In BIOS, the board is set to try keep the processor below 45 degrees C, and set to try keep the fan speed as low as possible (except the 12V test). We then compare the temperature rise over ambient (Delta T).

Results

| Ambient in C | CPU Temp in C | Fan RPM | Delta T in C | |

| Celeron/Pentium/i3 cooler idle | 14 | 23 | 1027 | 9 |

| Celeron/Pentium/i3 cooler load (PWM control) | 14 | 46 | 1271 | 32 |

| Celeron/Pentium/i3 cooler (12V) | 14 | 42 | 2000 | 28 |

| i5/i7 cooler idle | 15 | 24 | 1002 | 9 |

| i5/i7 cooler load (PWM Control) | 15 | 45 | 1002 | 30 |

| i5/i7 cooler (12V) | 14 | 42 | 2000 | 27 |

Full aluminium cooler: at idle and PWM-controlled load, the fan is barely audible. Idle has a slight whine but further away than 50cm it is not audible. At full load (PWM controlled) the fan spins slightly faster, and has less of a whine to it’s sound. Much nicer. At full 12V, the fan is very audible, and the whine returns. I would not recommend running the fan at 12v, considering the advantage here is just 4 degrees delta T.

Copper/Alu cooler: at idle and PWM-controlled load, the fan is once again barely audible. Idle has less whine than the all-aluminium cooler. At full load (PWM controlled) the fan spins slightly faster, and has less of a whine to it’s sound. Much nicer. The fan refused to run at full speed on a simple 12v molex to fan adapter so we had to make do with setting the fan speed to max in software. The noise was noticeably louder, but with no real whine to it at this speed.

Recommendations:

If you have a few bucks to spare, I would recommend changing your Celeron/Pentium/i3 cooler to the copper cored item. The combination of a higher rated fan and better heatsink design enables a quieter, and more appealing sound profile.

In the real world, it is not pure dB numbers that matter, but the sound profile of the fan and cooler assembly that will be most noticeable. Choosing fans with a lower pitch and balanced noise profile will sound rather different to a fan with a large change in profile across the RPM range, and/or has a higher pitches sound.

Aluminium Cooler: SFFr TESTED

Copper Core Cooler: SFFr APPROVED

Note: after testing I have realised that a higher wattage processor would have achieved stronger differences in results. Various reviews around the web point to the Pentium G620 being closer to a 40W processor than a 65W processor. I imagine the resulting differences will be more pronounced with a true 65w core i3 processor, and will endeavour to test this in the future.