So, you want to build a scratch mod? It’s something a lot of enthusiasts have thought about tackling over time. You reach a certain point and you’re no longer satisfied with simply modding existing cases. You want to get a little more creative, and as a result, a little more personal. The modding community is always growing, and as you see rigs that inspire you, the desire to create something truly unique becomes insatiable. Desire is a great thing, but it’s only part of the equation. You need to have a plan and the commitment to see the project through. A lot of modders don’t always know where to start, especially when it comes to building from scratch. Scratchbuilding may be the most challenging form of modding, but it’s also the most rewarding. As someone who’s used both methods, I’ve come to prefer scratch above all else. There is a certain intimidation factor, but overcoming any issues you may face along the way only help to strengthen your skillset. I’ve decided to give you all an overview of my design process, and show you the evolution of one my mods currently in the planning process. This particular case has not yet been seen outside of the Losias Brainstorming forum.

Computer modding really got its start from enthusiasts who were eager to overcome the case and hardware limitations at the time. Extra fan holes for added ventilation were usually one of the first additions. As time progressed, so did the complexity. Primitive water cooling, case lighting, and even sleeving started becoming accepted as extreme forms of modding. It wasn’t long before manufacturers sprung up to try and meet the demands of the growing niche. Today enthusiasts have thousands of options when it comes to customization, and what was once extreme, is now the norm. That’s where scratch build case modding takes over. It’s one of the only ways left to avoid the cookie cutter systems that are so common now. I’d even go so far as to say that no matter what you’ve added to your case, if you’ve not fired up the Dremel, it may not even qualify as a mod in the truest sense. However, that’s another debate altogether.

Inspiration can come from anywhere. Automobiles, architecture, nature, or even just the desire to build something from a defined set of goals. The source doesn’t matter, but the plan for seeing a project through, does. The more you can figure out beforehand, the less likely you are to come across issues during construction. That saves you time, and ultimately money in the long run. Not to mention that you’re less likely to get discouraged and give up. It may be cliche, but the saying, “He who fails to plan, plans to fail.” is completely appropriate.

Where do we begin?

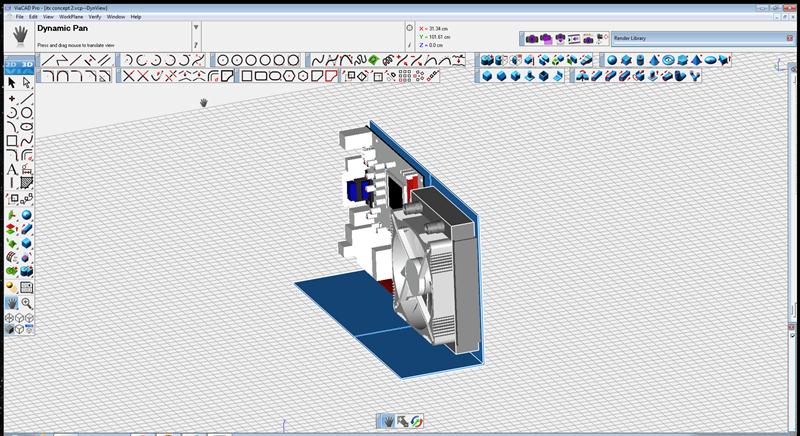

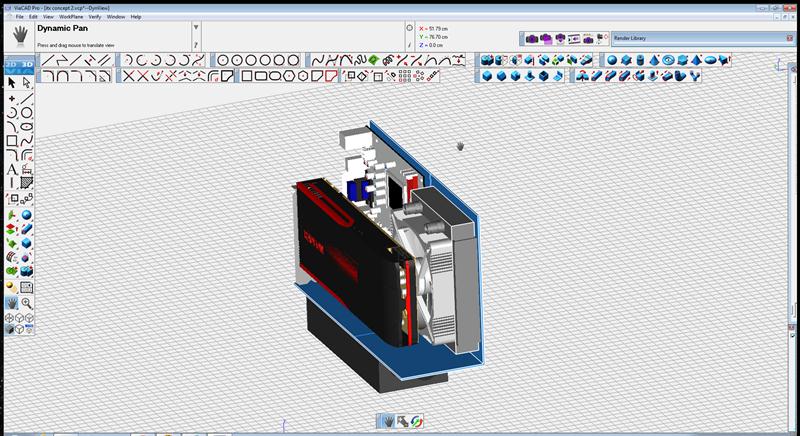

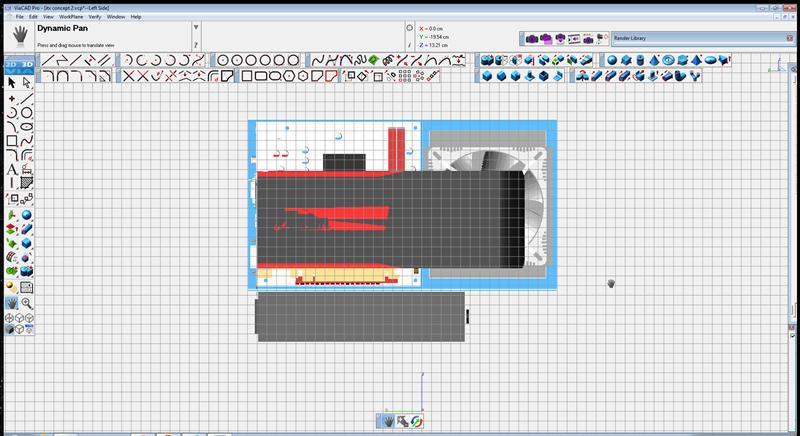

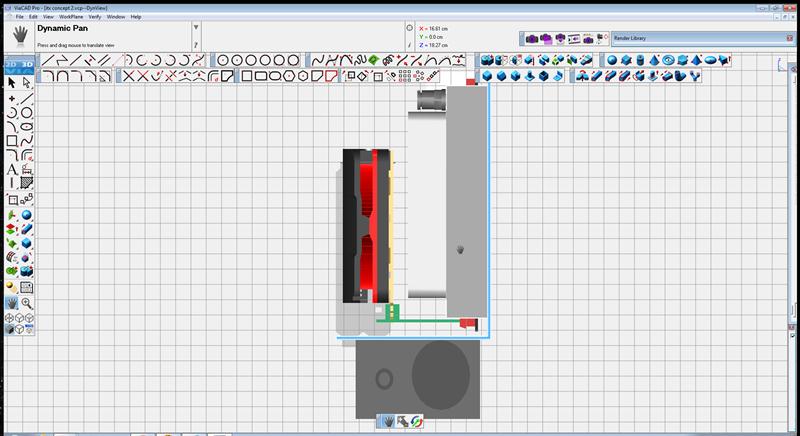

So, where do we start? One of the best possible tools for planning a case layout comes in the form of a copy of Sketchup, and a trip to The SketchUp Components Collection. You’ll find a lot of ready made PC components ready to download, and new ones are always getting added. I personally prefer ViaCAD Pro to Sketchup, but the concept is the same. Both programs allow you to import parts and design accordingly.

Since we deal primarily with SFF cases and modding here at Losias, the ability to place parts in 3 dimensions is a huge benefit to us. We are dealing with tighter clearances, and airflow is of the utmost importance. Every single component placed, will likely affect another in some way. Design efficiency can’t be overlooked just for the sake of cramming as many parts as possible into a case. Otherwise you’ll end up with a system that may be physically small, but doesn’t perform as it should. One of my design goals is to never compromise performance just to save space. I want both. That said, I’m not immune to wanting a case that’s cosmetically appealing, but never at the expense of function. That’s why I usually take an inside-out approach to modding. In other words, I get some concept of hardware placement first, and then design the case exterior around it.

I’m currently working on an ITX LAN gaming case. I needed the ability to hold high-end hardware in a durable, compact, and easily transported system. It also had to offer easy maintenance while ensuring it would run as cool as possible. SFF and easy don’t always go together. Confined spaces make clearance issues for anyone with hands bigger than a 3rd grader. That’s a design challenge I just have to work around.

Let’s get on with it then, shall we? After firing up ViaCAD, I imported a few of the key components and settled on a core layout. I’m utilizing an ITX board, full size GPU via card riser, Shuttle PSU, and an all-in-one cooling solution. While the actual brand of the components at this point doesn’t really matter, the spacing and layout do. The components in the below pics represent the clearances needed for the majority of the hardware that would ever find it’s way into this particular case.

As you can see, that’s a pretty good starting point. In the following articles, you’ll see the case evolve, and ideas planned, abandoned, and then revised as I work to find something I’m happy with. Until next time!